Tieto súbory cookies tvoria základ pre prevádzku našich webových stránok a umožňujú používanie základných funkcií, akými sú napríklad zabezpečené oblasti alebo online platby. Základnými cookies sú napr. zapamätanie prihlásenia, umožnenie prístupu k zabezpečeným oblastiam bez nutnosti opätovného prihlásenia, predvyplnenie formulárov a pod.

Lithium Recovery from Li Enriched Slag —Thermodynamic Study, Kinetic Study, and Dry Digestion

Expression of Interest

27. novembra 2020

SLOVENSKO BUDE MAŤ NÁRODNÉ BATÉRIOVÉ CENTRUM – NBC

9. decembra 2020Lithium Recovery from Li Enriched Slag —Thermodynamic Study, Kinetic Study, and Dry Digestion

A Combined Pyro- and Hydrometallurgical Approach to Recycle Pyrolyzed Lithium-Ion Battery Black Mass Part 2: Lithium Recovery from Li Enriched Slag —Thermodynamic Study, Kinetic Study, and Dry Digestion, Jakub Klimko, Dušan Oráč, Andrea Miškufová, Claudia Vonderstein, Christian Dertmann, Marcus Sommerfeld, Bernd Friedrich a Tomáš Havlík vedecký článok vydaný: 23 novembra 2020, 26 strán

Find the .pdf version at the link above or go to the MDPI, an academic publisher of open access journals at Journals / Metals / Volume 10 / Issue 11 / 10.3390/met10111558

Jakub Klimko 1,* , Dušan Oráč 1 , Andrea Miškufová 1, Claudia Vonderstein 2, Christian Dertmann 2, Marcus Sommerfeld 2 , Bernd Friedrich 2 and Tomáš Havlík 1 1 Institute of Recycling Technologies, Faculty of Materials, Metallurgy and Recycling, Technical University of Košice, Letna 9, 04200 Košice, Slovakia; dusan.orac@tuke.sk (D.O.); andrea.miskufova@tuke.sk (A.M.); tomas.havlik@tuke.sk (T.H.) 2 IME Process Metallurgy and Metal Recycling, Institute of RWTH Aachen University, Intzestraße 3, 52056 Aachen, Germany; cvonderstein@ime-aachen.de (C.V.); cdertmann@ime-aachen.de (C.D.); msommerfeld@ime-aachen.de (M.S.); bfriedrich@ime-aachen.de (B.F.) * Correspondence: jakub.klimko@tuke.sk; Tel.: +421-905-507-327

Received: 28 October 2020; Accepted: 19 November 2020; Published: 23 November 2020

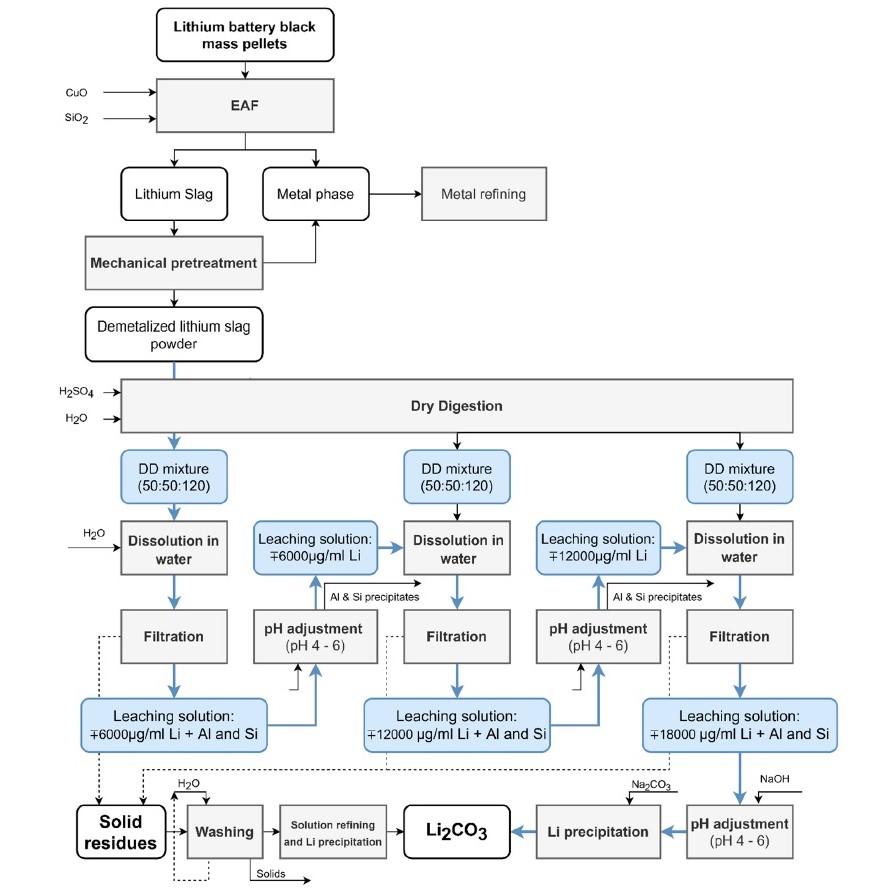

Abstract: Due to the increasing demand for battery raw materials, such as cobalt, nickel, manganese, and lithium, the extraction of these metals, not only from primary, but also from secondary sources, is becoming increasingly important. Spent lithium-ion batteries (LIBs) represent a potential source of raw materials. One possible approach for an optimized recovery of valuable metals from spent LIBs is a combined pyro- and hydrometallurgical process. The generation of mixed cobalt, nickel, and copper alloy and lithium slag as intermediate products in an electric arc furnace is investigated in part 1. Hydrometallurgical recovery of lithium from the Li slag is investigated in part 2 of this article. Kinetic study has shown that the leaching of slag in H2SO4 takes place according to the 3-dimensional diffusion model and the activation energy is 22–24 kJ/mol. Leaching of the silicon from slag is causing formation of gels, which complicates filtration and further recovery of lithium from solutions. The thermodynamic study presented in the work describes the reasons for the formation of gels and the possibilities of their prevention by SiO2 precipitation. Based on these findings, the Li slag was treated by the dry digestion (DD) method followed by dissolution in water. The silicon leaching efficiency was significantly reduced from 50% in the direct leaching experiment to 5% in the DD experiment followed by dissolution, while the high leaching efficiency of lithium was maintained. The study takes into account the preparation of solutions for the future trouble-free acquisition of marketable products from solutions.

Keywords: lithium-ion battery; recycling; lithium; slag; hydrometallurgy; leaching; dry digestion; critical raw materials

About UNIVNET

The Slovak University of Technology launched an initiative bringing together several research universities (University of Economics in Bratislava, Technical University of Košice, University of Žilina and Technical University in Zvolen) and with the Automotive Industry Association of the Slovak Republic founded the UNIVNET association in order to carry out research and development activities in the recycling and waste recovery, particularly in the automotive industry, since this is a dominant part of industry in Slovakia.

If you are interested in partnership or need further information please contact Dr.h.c. prof. Ing. Ľubomír Šooš, PhD., Dean, Faculty of Mechanical Engineering, SLOVAK UNIVERSITY OF TECHNOLOGY IN BRATISLAVA, Phone: +421 2 572 965 39, E-mail: lubomir.soos at stuba.sk, www.sjf.stuba.sk

You can find us on the social networks LinkedIn and Facebook under the username UNIVNET Research.